High shear granulators combine fantastic powdered items by using a binder liquid to variety substantial agglomerates. These agglomerates are then damaged down into granules with the desired particle dimensions.

To forestall area agglomeration, powdered components should be extra cautiously and slowly and gradually. On the other hand, if added as well slowly and gradually, the continual section could attain its concentrate on parameters prior to all dispersed particles are thoroughly integrated, impacting throughput and financial gain margins in mass manufacturing.

Precisely simulating actual-entire world ailments with CFD Assessment is complex and demands Highly developed know-how. Because of this, the design of high shear mixers often depends on empirical solutions, concentrating on progress by application-certain testing for various goods and producing setups. Picking out the ideal high shear mixer in your sector—irrespective of whether for batch mixing, in-line mixing, or ongoing processing—is dependent upon comprehension your software needs, wanted results, and generation scale.

Given that oil is nonpolar rather than attracted to water molecules, and because oil is usually less dense than water, it tends to float and independent through the drinking water. The high shear mixer’s intention is to continually break down these droplets to stop this normal separation by implementing rigorous shear Power.

High shear mixers Increase the emulsification method by reducing droplet size, raising surface location, and ensuring very long-term physical security of your emulsion—a crucial necessity for high-quality control in items like lotions, creams, sauces, and prescription drugs.

A fluid is any compound in a very liquid or gaseous condition that could circulation freely and isn't constrained by floor results. The actions and Attributes of fluids, which include their viscosity, density, and stream patterns, are examined in the area of fluid mechanics.

We use cookies to give you an even better searching practical experience and review site visitors. Read about how we use cookies and how you can high shear mixer control them on our Privateness Coverage.

Applied throughout various industries, they enrich the sustainability and performance of production processes globally.

Selecting the correct mixing engineering is essential; it’s don't just a big processing criterion — making certain the creation of a homogenous ultimate item that’s free from ‘fish eyes’ and lumps during the shortest attainable time — but additionally affects the batch cycle time and the overall cost of ownership.

Vortices are designed both higher than and below the mixing head, drawing the mixture into the head and expelling it radially with the stator slots. Also, these vortices can attract agglomerates floating over the area into the mixing procedure.

More quickly Processing Instances: The extreme mixing motion of high shear mixers significantly cuts down processing situations as compared to agitators. This interprets to enhanced efficiency and output output.

Broader Variety of Applications: High shear mixers can take care of a broader range of viscosities, from lower-viscosity liquids to highly viscous pastes. Agitators wrestle with thicker components.

This accelerated and uneven circulation is essential for breaking apart droplets or particles suspended inside the mixture, leading to emulsion, dispersion, and homogenization of your components—An important action in the formulation of creams, suspensions, and emulsions in many industries.

A stationary ingredient might be utilised together While using the rotor, and it is often called the stator. The stator makes a close-clearance gap amongst the rotor and by itself and varieties an incredibly high-shear zone for the fabric mainly because it exits the rotor.

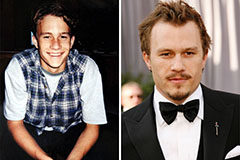

Heath Ledger Then & Now!

Heath Ledger Then & Now! Barry Watson Then & Now!

Barry Watson Then & Now! Matilda Ledger Then & Now!

Matilda Ledger Then & Now! Susan Dey Then & Now!

Susan Dey Then & Now! Tina Louise Then & Now!

Tina Louise Then & Now!